Inspection Services

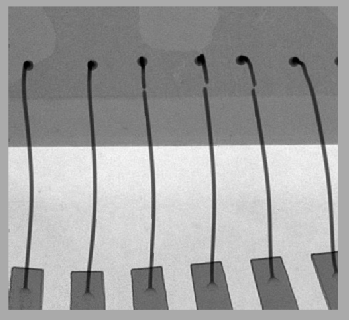

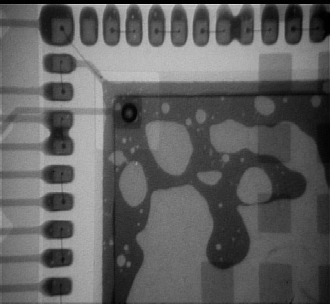

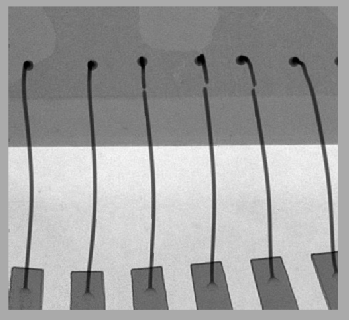

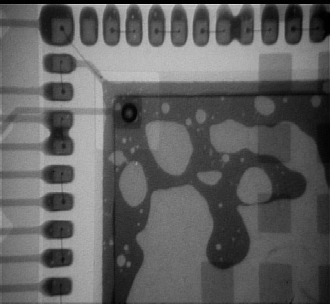

WOW Circuit X-Ray Inspection services provide a inside underneath look to confirm rework, help diagnose process problems and make sure the inspection criteria of your customers are adhered to. Components such as BGAs and Leadless parts Including QFN’s with belly pads per their design and attachment process to the PCB require an x-ray system to confirm attachment of the device and to ensure that the assembly or rework process is in control. Wetting characteristics, uniform collapse of the solder balls, the minimization of voiding as well as the integrity of the wire bonds can be assured with the use of x-ray imaging. By verifying the interface of the ball on the package to the PCB can be confirmed by manipulating the X-Ray system to help better see the interconnect.

Every circuit board we process either Production / Prototype run or for BGA rework is carefully inspected using our Verifier HR X-Ray machine. For higher level inspection we offer a High level Dage X-ray system to ensure the BGA rework meets the highest quality levels. Either system will pin point defects including solder joint shorts, opens, and voids. Fault finding is demanding so X-ray systems must provide, as a minimum, high resolution, high magnification and high contrast X-ray images.

These X-ray systems provide highly detailed real-time x-ray images. The extensive grayscale definition and oblique angle views deliver the superb detail demanded for proper diagnosis.

Visual Inspection

We offer IPC-610 visual inspection services using fully certified IPC inspectors.

X-Ray Inspection on BGA’s not only detects bridging of solder joints but also is used for void detection and analysis.

QFN’s require verification as well for bridging and void detection since they have contacts under the device. At WOW Circuits, every Leadless Part, BGA and Flip Chips are inspected for shorts and voids

Includes removal and salvage of BGA and surface mount components, connectors and many other component types.