X-Ray SERVICES

WOW Circuits is the fastest Rework / Modification service provider in the Upper Midwest. We are specialists when it comes to circuit board repair and rework of assembled circuit boards and we have been been the savior of many projects and assemblies for many engineers. Whether you need help with a thousand circuit boards or just a few, we can complete the job and get your circuit boards back to you for a charge that's generally just a fraction of the circuit board's value. And every project is backed by our unconditional guarantee.

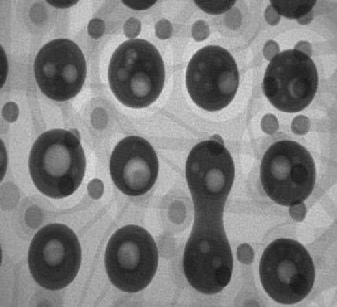

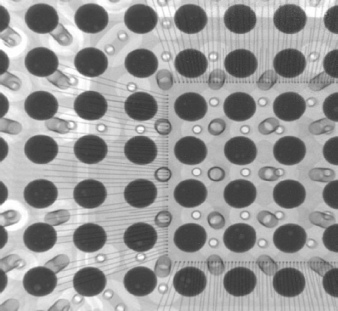

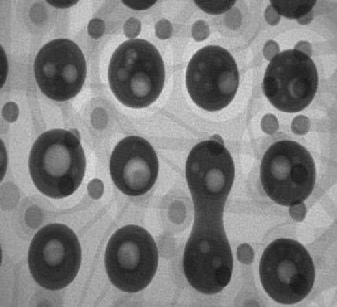

2D X-Ray for Inspection of hidden solder joints (e.g. BGA inspection of solder ball shape and shrink hole formation, shorts and voids)

X-Ray is useful for various things. It can also see internal aspects of the part for failure analysis

If internal evaluation is required, X-Ray can be used to see if there is any issues obvious to the naked eye.

Internal Failure Analysis

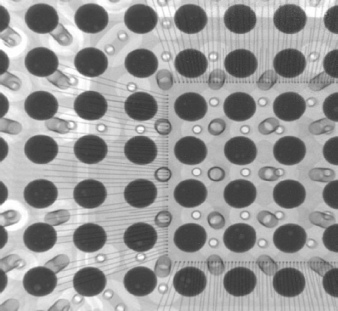

Wire bonding is widely used for first-level interconnection of semiconductor die to component leads or pads. Inspection of bonding areas (e.g. broken wire) and lead-frames may be required after package is sealed.

X-ray used for failure analysis

Using a real-time, non-destructive method like x-ray inspection to monitor the internal structures of the IC package during manufacture is critical

X-ray examination is also valuable as a post-qualification testing analytical tool, to identify and document issues such as wire breakage degradation caused by accelerated temperature cycling testing.

When you know its defective, X-Ray will verify where the fault is and confirm.

The illustrations show just how clearly X-ray documentation is able to identify binding-related quality issues and field failure modes.

When High end X-ray is required we can provide that level of service to our customers